Fuel oil purifiers play a critical role in ensuring the efficiency and longevity of engines and machinery that rely on fuel oil. These specialized devices are designed to remove contaminants and impurities from fuel oil, thereby improving its quality and ensuring optimal performance. In this article, we delve into the five primary purposes of the fuel oil purifier, supported by data and industry insights.

1. Removal of Solid Particles

One of the primary functions of a fuel oil purifier is to remove solid particles from the fuel oil. Solid contaminants such as dirt, rust, and abrasive particles can enter the fuel oil during storage, transportation, or handling. These particles pose a significant risk to the engine components as they can cause abrasion, wear, and damage to sensitive parts like fuel injectors and pumps.

According to industry standards, fuel oil purifiers are designed to effectively filter out solid particles as small as microns. This level of filtration ensures that the fuel oil supplied to the engine is clean and free from any abrasive materials that could compromise performance and reliability.

2. Separation of Water and Sediments

Another crucial purpose of the fuel oil purifier is to separate water and sediments from the fuel oil. Water and sediments can accumulate in fuel oil tanks due to condensation or contamination during storage and transportation. When water mixes with fuel oil, it can promote microbial growth and lead to corrosion within the engine system.

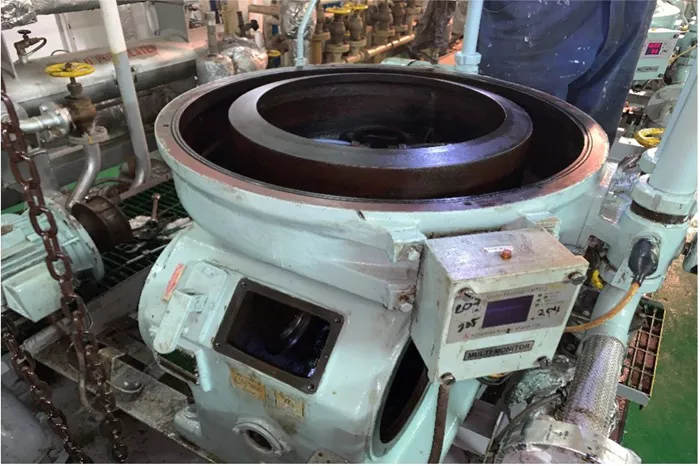

Fuel oil purifiers utilize centrifugal force or coalescing filters to separate water and sediments from the fuel oil effectively. By removing these contaminants, purifiers prevent potential engine malfunctions, reduce maintenance costs, and extend the operational life of engines and machinery.

3. Reduction of Sulfur Content

In recent years, there has been an increased focus on reducing the sulfur content in fuel oils to comply with environmental regulations and improve air quality. High sulfur levels in fuel oil contribute to the emission of sulfur oxides (SOx), which are harmful pollutants known to cause respiratory issues and environmental damage.

Fuel oil purifiers equipped with desulfurization technologies are designed to reduce sulfur content in compliance with regulatory standards. These technologies may include chemical treatments or specialized filters that target sulfur compounds, thereby producing cleaner and less polluting fuel oil for industrial and maritime applications.

See also: How Does A Fuel Oil Purifier Work?

4. Preservation of Fuel Quality

Maintaining the quality of fuel oil is essential for ensuring consistent engine performance and efficiency. Over time, fuel oil can degrade due to oxidation, contamination, or chemical reactions, leading to increased viscosity and decreased combustibility. These changes can result in poor engine performance, higher fuel consumption, and increased emissions.

Fuel oil purifiers help preserve fuel quality by removing contaminants, stabilizing chemical properties, and preventing oxidation. By maintaining clean and stable fuel oil, purifiers ensure reliable engine operation, reduce operational costs, and minimize environmental impact.

5. Enhancement of Engine Efficiency

Ultimately, the primary goal of a fuel oil purifier is to enhance engine efficiency. Clean and high-quality fuel oil allows engines to operate at optimal performance levels, achieving better fuel combustion, reduced emissions, and extended maintenance intervals. By ensuring that engines receive clean and purified fuel oil, purifiers contribute to overall operational efficiency and productivity in various industrial sectors.

Conclusion

Fuel oil purifiers are indispensable devices that play a crucial role in maintaining the reliability, efficiency, and environmental compliance of engines and machinery. By effectively removing contaminants, separating water and sediments, reducing sulfur content, preserving fuel quality, and enhancing engine efficiency, these devices contribute to smoother operations and reduced maintenance costs in industrial and maritime applications.

As environmental regulations continue to evolve and technological advancements drive innovation in fuel oil purification, the importance of these devices is expected to grow. Investing in high-quality fuel oil purifiers not only ensures regulatory compliance but also enhances the sustainability and longevity of engine systems in a rapidly changing global landscape.

Related topics:

Can You Burn Diesel In A Fuel Oil Furnace?