Turning crude oil into gasoline is a complex process that involves multiple stages of refining and treatment. Crude oil, a naturally occurring fossil fuel extracted from the ground, undergoes extensive processing to produce gasoline, which fuels vehicles and machinery worldwide. This article explores the journey of crude oil from the well to the pump, detailing each step in the refining process, the factors influencing gasoline production, and the environmental considerations associated with this essential fuel.

The Origins of Crude Oil

Formation and Composition

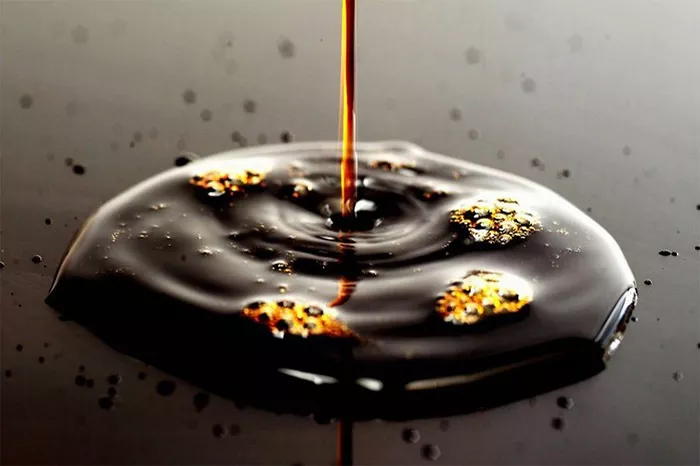

Crude oil forms over millions of years from the decomposition of organic materials such as plankton and algae that settled on the seabed. Over time, these organic materials undergo heat and pressure, transforming into hydrocarbons—the primary components of crude oil. The composition of crude oil varies depending on its source, with different regions yielding oil of varying densities and chemical compositions.

Exploration and Extraction

The exploration and extraction of crude oil begin with geological surveys and drilling operations. Geologists identify potential oil reservoirs beneath the Earth’s surface, often located in sedimentary rock formations. Once a viable site is identified, drilling rigs are employed to extract crude oil from the reservoirs deep underground. Advanced drilling techniques, such as horizontal drilling and hydraulic fracturing (fracking), have expanded the accessibility of previously inaccessible oil reserves.

The Refining Process

Separation by Distillation

Upon extraction, crude oil undergoes refining, a process that separates it into various components based on their boiling points. The first step in refining crude oil is distillation, which takes place in a distillation tower—a tall, vertical structure with multiple chambers. The crude oil is heated at the bottom of the tower, causing it to vaporize. As the vapors rise through the tower, they cool and condense at different heights based on their boiling points. This separation yields fractions such as gasoline, diesel, kerosene, and heavy fuel oils.

Conversion Processes: Cracking and Reforming

After distillation, certain fractions of crude oil undergo conversion processes to enhance their properties. Catalytic cracking involves breaking down larger hydrocarbon molecules into smaller, more valuable ones. This process increases the yield of gasoline components and other light hydrocarbons. Catalytic reforming, on the other hand, rearranges the molecular structure of hydrocarbons to improve the octane rating of gasoline, enhancing its combustion efficiency.

Treating and Blending

Once the desired fractions are obtained, they undergo treatment to remove impurities such as sulfur, nitrogen, and metals. Desulfurization, in particular, is crucial for producing cleaner fuels and reducing emissions. After treatment, the refined fractions are blended to achieve specific fuel characteristics. This blending process ensures that the gasoline meets regulatory standards and performs effectively in vehicles and machinery.

Quality Control and Testing

Ensuring Compliance and Safety

Throughout the refining process, stringent quality control measures are implemented to ensure the safety and compliance of gasoline products. Samples from each batch of gasoline are tested in laboratories to verify that they meet specifications for purity, performance, and environmental impact. These tests include measuring octane ratings, volatility, and emissions characteristics. Compliance with regulatory standards, such as those set by environmental agencies, is essential to guaranteeing the quality and safety of gasoline.

Continuous Improvement and Innovation

Refineries continually strive to improve their processes and technologies to enhance the efficiency and environmental sustainability of gasoline production. Innovations in refining techniques, such as advanced catalysts and process optimization, contribute to reducing energy consumption, minimizing waste, and lowering emissions. Research and development efforts focus on developing cleaner fuels, integrating renewable resources, and meeting evolving regulatory requirements.

Environmental Impact and Sustainability

Addressing Environmental Concerns

The production and consumption of gasoline have significant environmental implications, primarily related to air quality, greenhouse gas emissions, and resource depletion. While advancements in refining technology have reduced the environmental footprint of gasoline production, challenges remain in mitigating its impact on climate change and local ecosystems. Strategies such as carbon capture and storage (CCS) and the use of biofuels aim to reduce greenhouse gas emissions associated with gasoline production and consumption.

Regulatory Framework and Compliance

Governments worldwide impose strict regulations on gasoline production to protect public health and the environment. These regulations set limits on emissions of pollutants such as sulfur dioxide (SO2), nitrogen oxides (NOx), volatile organic compounds (VOCs), and particulate matter. Refineries must adhere to these standards through the adoption of cleaner technologies, the implementation of emission controls, and regular monitoring and reporting of environmental performance.

See also: How Is Reformulated Gasoline Made?

Distribution and Consumption

Transportation and Storage

Once refined, gasoline is transported from refineries to distribution terminals and storage facilities through pipelines, tanker trucks, and barges. Distribution networks ensure a reliable supply of gasoline to retail stations and industrial consumers across regions and countries. Stringent safety protocols govern the transportation and storage of gasoline to prevent spills, leaks, and other accidents that could harm human health and the environment.

Utilization in Vehicles and Machinery

Gasoline is predominantly used as a fuel for internal combustion engines in automobiles, motorcycles, trucks, and other vehicles. It provides the energy necessary for engine operation, enabling transportation and mobility. Gasoline’s combustion properties, including its octane rating and energy density, contribute to efficient engine performance and vehicle acceleration. The widespread availability and affordability of gasoline make it a preferred choice for powering personal and commercial vehicles worldwide.

Economic Considerations and Market Dynamics

Pricing and Market Trends

The price of gasoline is influenced by various factors, including crude oil prices, refining costs, taxes, supply and demand dynamics, and geopolitical events. Fluctuations in global oil markets can lead to volatility in gasoline prices, affecting consumers, businesses, and economies. Governments often implement fuel subsidies or taxation policies to stabilize prices and manage consumption patterns. Understanding these market dynamics is crucial for stakeholders in the energy sector and consumers alike.

Economic Impact and Energy Security

The availability and affordability of gasoline play a vital role in economic growth and energy security. Dependence on imported oil and fluctuations in gasoline prices can impact national economies and household budgets. Diversifying energy sources, promoting energy efficiency, and investing in renewable fuels are strategies aimed at enhancing energy security and reducing reliance on fossil fuels. Balancing economic considerations with environmental sustainability remains a priority for policymakers and industry leaders.

Future Outlook and Innovations

Advancements in Fuel Technology

The future of gasoline production is shaped by ongoing advancements in fuel technology and environmental stewardship. Research efforts focus on developing alternative fuels, improving fuel efficiency, and reducing emissions from combustion engines. Innovations such as electric vehicles (EVs), hydrogen fuel cells, and sustainable biofuels offer promising alternatives to conventional gasoline. These technologies aim to address climate change, enhance air quality, and promote energy independence.

Sustainable Practices and Policies

Global efforts to mitigate climate change and reduce greenhouse gas emissions are driving the adoption of sustainable practices and policies in gasoline production. Initiatives such as carbon pricing, emission trading schemes, and renewable fuel mandates incentivize refineries to invest in cleaner technologies and reduce their environmental footprint. Collaboration among governments, industries, and stakeholders is essential to achieving sustainable development goals and ensuring a resilient energy future.

Conclusion

The journey of crude oil into gasoline underscores the intricate process and global significance of refining. From extraction to distribution, each stage of gasoline production involves technological innovation, regulatory compliance, and environmental stewardship. While challenges persist in managing environmental impacts and ensuring energy security, ongoing advancements in fuel technology offer opportunities for a more sustainable energy future. By embracing innovation, promoting efficiency, and addressing environmental concerns, the refining industry continues to play a vital role in meeting global energy demands while safeguarding the planet for future generations.

Related topics:

The Link Between Crude Oil And Gasoline Prices[Revealed]