Diesel fuel is a critical energy source powering numerous engines and machinery worldwide. Understanding its production process is essential for appreciating its role in various industries. This article will explore how diesel fuel is made from crude oil, detailing the entire process from extraction to refining and distribution.

The Origin of Crude Oil

Crude oil extraction and composition

Crude oil is a naturally occurring fossil fuel formed from the remains of ancient marine organisms. Over millions of years, heat and pressure transformed these remains into a mixture of hydrocarbons. The extraction process involves drilling wells into the Earth’s crust to access underground oil reservoirs.

The composition of crude oil

Crude oil is a complex mixture of hydrocarbons, which are compounds composed primarily of hydrogen and carbon. It also contains sulfur, nitrogen, oxygen, and trace metals. The specific composition varies depending on the geographic location of the oil field. The presence of different hydrocarbons makes crude oil a valuable resource for producing various fuels, including diesel.

Refining Crude Oil

The refinery process overview

Once crude oil is extracted, it is transported to refineries for processing. Refining transforms crude oil into valuable products such as gasoline, diesel, jet fuel, and lubricants. The refining process involves several key steps, each designed to separate and purify the different components of crude oil.

Distillation: The first step in refining

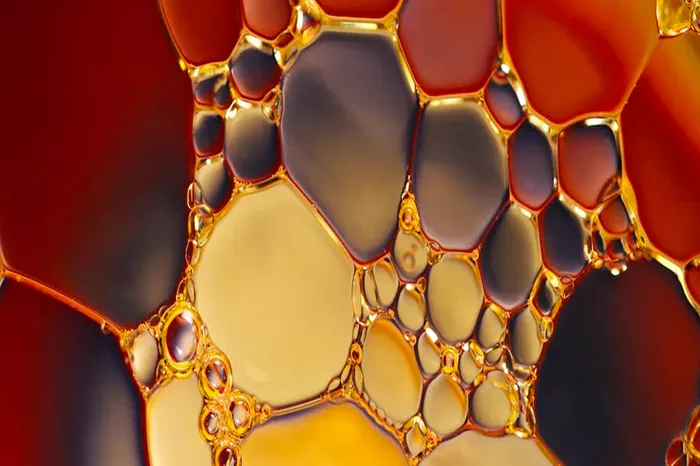

The first step in refining crude oil is distillation, also known as fractional distillation. In this process, crude oil is heated in a distillation column, causing it to vaporize. As the vapor rises through the column, it cools and condenses at different temperatures, allowing the separation of various hydrocarbons based on their boiling points.

The role of atmospheric distillation

In atmospheric distillation, the crude oil is heated to about 350-400 degrees Celsius. The lighter hydrocarbons, such as gasoline and naphtha, condense at higher levels in the column, while heavier hydrocarbons, including diesel, condense lower down. This initial separation is crucial for producing diesel fuel.

The Production of Diesel Fuel

Hydrocracking and catalytic cracking

After the initial distillation, the heavier fractions, including those destined to become diesel, undergo further processing. Two key processes used are hydrocracking and catalytic cracking.

Hydrocracking involves reacting the heavy hydrocarbons with hydrogen under high pressure and temperature in the presence of a catalyst. This process breaks down large molecules into smaller, more valuable ones, including diesel.

Catalytic cracking, on the other hand, uses a catalyst to break down heavy hydrocarbons into lighter products. This process is essential for converting less valuable fractions into more useful fuels.

Desulfurization: Removing impurities

One of the critical steps in diesel production is desulfurization. Diesel fuel contains sulfur compounds that can contribute to air pollution when burned. To produce cleaner diesel, refineries use processes such as hydrodesulfurization, where sulfur is removed by reacting the fuel with hydrogen in the presence of a catalyst. This step is vital for meeting environmental regulations and producing high-quality diesel fuel.

See also: Is Diesel Fuel Made From Crude Oil?

Enhancing Diesel Quality

Additives and blending

To improve the performance and stability of diesel fuel, refineries add various additives and blend different fuel streams. Additives can enhance lubricity, reduce emissions, and prevent the formation of deposits in the engine. Blending involves mixing different fractions of refined oil to achieve the desired properties, such as cetane number and cold flow characteristics.

Cetane number and its importance

The cetane number is a measure of the combustion quality of diesel fuel. A higher cetane number indicates better ignition properties, leading to smoother and more efficient engine operation. Refineries use additives and blending techniques to ensure that diesel fuel meets the required cetane number specifications.

Distribution and Storage

Transportation of diesel fuel

Once diesel fuel is refined and meets quality standards, it is transported to distribution centers and fuel stations. Transportation methods include pipelines, tankers, and trucks. Pipelines are the most efficient means of moving large volumes of diesel over long distances, while tankers and trucks are used for shorter distances and more flexible delivery options.

Storage and handling

Proper storage and handling of diesel fuel are essential to maintain its quality and prevent contamination. Diesel fuel is typically stored in large tanks at refineries, distribution centers, and fuel stations. These tanks must be kept clean and free of water and other contaminants. Regular testing and maintenance ensure that the fuel remains in good condition until it is used.

Environmental Considerations

Reducing emissions and improving sustainability

The production and use of diesel fuel have significant environmental impacts. Refineries are continuously working to reduce emissions and improve the sustainability of diesel fuel. This includes developing cleaner production processes, using renewable feedstocks, and improving fuel efficiency.

The role of renewable diesel

Renewable diesel is an emerging alternative to traditional diesel fuel. It is produced from renewable resources such as vegetable oils, animal fats, and waste materials. Renewable diesel has similar properties to conventional diesel but with lower greenhouse gas emissions. Its production and use are growing as part of efforts to reduce the environmental impact of transportation fuels.

The Future of Diesel Fuel

Advancements in refining technology

The refining industry is constantly evolving, with new technologies and processes being developed to improve efficiency and reduce environmental impact. Advanced refining techniques, such as gas-to-liquids (GTL) and biomass-to-liquids (BTL), offer promising avenues for producing cleaner diesel fuel.

The impact of regulations

Regulations play a crucial role in shaping the future of diesel fuel production. Governments around the world are implementing stricter emission standards and promoting the use of cleaner fuels. Refineries must adapt to these regulations by investing in new technologies and processes to produce compliant diesel fuel.

Conclusion

Diesel fuel production from crude oil is a complex and multi-step process involving extraction, refining, and distribution. Understanding this process helps appreciate the intricate work required to produce the fuel that powers many aspects of our modern world. As the industry advances and environmental considerations become more critical, the production of diesel fuel will continue to evolve, aiming for greater efficiency and sustainability.

By exploring the various stages of diesel fuel production, from the origin of crude oil to the final product, this article highlights the importance of refining technology and environmental considerations in shaping the future of diesel fuel. The ongoing advancements in refining processes and the growing emphasis on cleaner, renewable alternatives will play a pivotal role in ensuring a sustainable energy future.

Related topics: